Cooper Coated Coil: How Sustainability Shapes Our Business

At Cooper Coated Coil we take sustainability seriously. Our responsibility as an international manufacturing business stretches around the world to our customers, our suppliers, our employees, our communities, and our world.

Our focus is built upon five points that form the basis for all our activities.

Raw Materials

The very essence of both the Steel and Aluminium we use is the fact that they are materials that can be infinitely recycled and are 100% recyclable without loss of quality – the ideal sustainable materials! This reduces energy, emissions and water consumption, plus saves on natural resources.

Our coatings play a key role in our business and are chemically complex, so we set exacting standards to ensure they are safe – we ensure that over 95% of the coating is applied to the substrate to minimise waste. We only use coatings that don’t contain PFOA and BPA, and we have made a further commitment to be 100% free of NMP based coatings by the end of 2022. Learn more here.

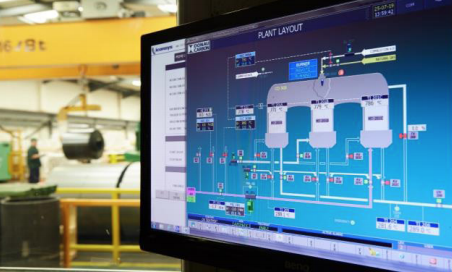

Our Process

The industrial scale of our application method means that it is the most environmentally friendly process as it minimises emissions, reduces energy consumption and waste.

The industrial scale of our application method means that it is the most environmentally friendly process as it minimises emissions, reduces energy consumption and waste.

To mitigate the harmful effects of VOC’s, using a Regenerative Thermal Oxidiser (RTO) to destroy the VOC gases released in the process to prevent them from entering into the atmosphere.

All water used in the process is cleaned and re-oxygenated and returned to the water supply as monitored by our local water authority. Learn more here.

Customer benefits

The nature of our process means that we deliver a pre-coated metal, cut to the perfect size ready for use, improving productivity and yields for our customers.

Customers also benefit from eliminating the need for their own paint lines which can remove a bottleneck in their operation.

Environmental management becomes simpler as the compliance and disposal of waste associated with the coating operation is handled by us. This leaves our customers to concentrate on their core competencies and leave the coating to us! Learn more here.

Waste Management

Through advance planning we aim to utilise over 92% of all the metal we coat, with the scrap 100% recycled – 95% of all coatings are utilised.

Packaging materials contain timber that is only sourced from FSE accredited suppliers and much of the steel wrapping is our own recycled coated metal.

All our waste is separated and recycled responsibly wherever possible. Learn more here.

Our people…our communities

A business is nothing without its people. Our customers, our suppliers, our employees and their communities are all an integral part of our business and we have important responsibilities.

The move to new offices and a blanking facility at Steelpark Way has allowed us to provide optimal working conditions at both of our sites and a positive working environment for all of our employees.

We support local community causes, from the supply of kit to junior sports teams, to financial support for up and coming athletes of the future. Learn more here.

What does all this mean for Cooper Coated Coil?

Our management of environmental factors plays a fundamental part of the sustainability of everything that we do, from the materials we use through to the setting of the highest standards in our processes and the support we provide for our people and communities.

Into the latter part of 2020 and beyond, we are continuously looking to take our responsibilities further and to continue to strive for the very best standards in our field.