GlideXTM

PFA

GLIDE-X PFA is a unique non-stick specification that is based on the technology pf PFA; a specialised fluoropolymer used in industrial bakeries & high protein environments.

Now available as a coil coated system for the first time, Glide-X PFA offers an effective hard wearing barrier providing excellent non-stick performance – particularly in sweet and pastry environments with high continuous use temperatures of 250C, superior stain & chemical resistance and a greater toughness than PTFE. Testing shows excellent non-stick performance with high protein foods such as fish, fats & sugars with little staining.

The specification is recommended for utilisation in oven trays, professional bakeware, high end baking & grilling as well as for use in small electrical appliances such as raclettes, rotary/air fryers, fish grills and contact grills.

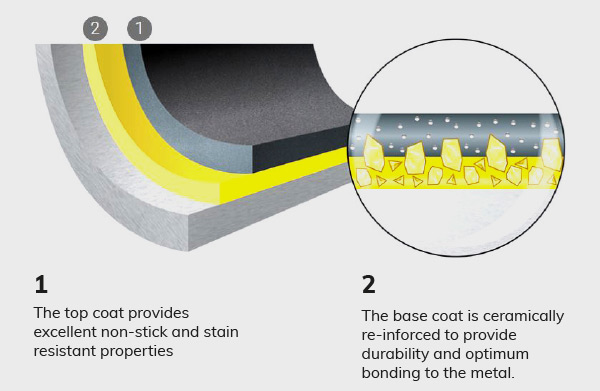

GLIDE-X is a registered trade mark of Cooper Coated Coil Limited and is the brand given to the premium performance 2-coat reinforced non-stick coating by coil coating application.

Coating Features

GLIDE-X PFA is a double layer system that utilises the latest coil coating technology thermally bonding the coating to the substrate ensuring the best performance from the metal and the coating.

Substrate

*Dependent upon alloy/temper/width

Characteristics

No of Layers 2

Coating thickness μm 10-14

Re-inforced base coat Yes

Curing Temperature ˚C 370

In use temperature ˚C 250

Scratch resistance ****

Abrasion resistance *****

Corrosion resistance *****

Stain resistance *****

Non-stick Effect *****

Testing Methods

GLIDE-X PFA is tested for

- Suitability for Food Contact

- Visual aspect

- Coating thickness

- Adhesion

- Flexibility

Non-stick Tests

- Chicken Roaster test

- Steak test

- Baking test

- Egg test

- Jam test

Presentation of Material

GLIDE-X PFA is packaged according to the standards of the receiving country and despatched by lorry or container to the final destination.

Finishing Service

GLIDE-X PFA can be supplied cut to size in coil and sheet form Coil Slitting

Sheet Blanking

Further Processing

GLIDE-X PFA is formulated to withstand further processing such as:

- Deep drawing

- Folding & roll forming

- Punching, notching and perforating

- Protective polymask film can be applied for additional security

These processes should be discussed in advance to ensure compatibility of the substrate.

The Trial Approval Process is there to ensure that GLIDE-X PFA works through the further processing to arrive at the consumer looking good and performing well.

Gallery