Industrial Bakeware

The improvement in non-stick performance of pre-coated metal in recent years has resulted in specifications that can be considered as a realistic alternative to traditional sprayed coating.

The supply route for Industrial bakeware products is that the forms are fabricated from Aluminium or Aluminised Steel then sent away for spray coating with PTFE/PFA/FEP non-stick or silicone glaze. Once the product result in the coatings becoming less effective, the form are shot-blasted, repaired then re-coated ready for re-use.

CCC pre-coated options can be useful in shortening the manufacturing cycle and units costs when considered for trays and re-heat baguette forms.

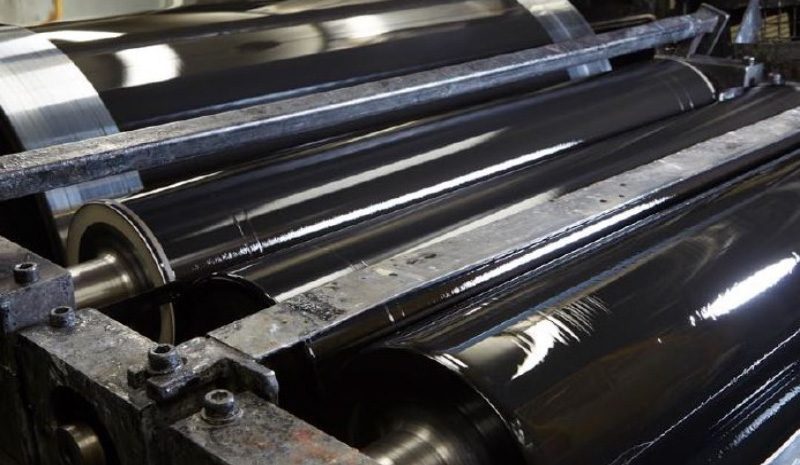

Coatings

CCC offers a range of non-stick coatings based on PTFE and PFA fluoropolymers. PTFE provides a general purpose non-stick suitable for many applications and the PFA option gives a superior performance in demanding sweet and high protein applications.

There are 2 and 3-coat options that provide a coating of thickness between 12 and 24 microns. All options have a primer that is corrosion enhanced and ceramically re-inforced for extended life and durability. The top layers are rich in fluoropolymer so the multi-layers provide a great combination and performance.

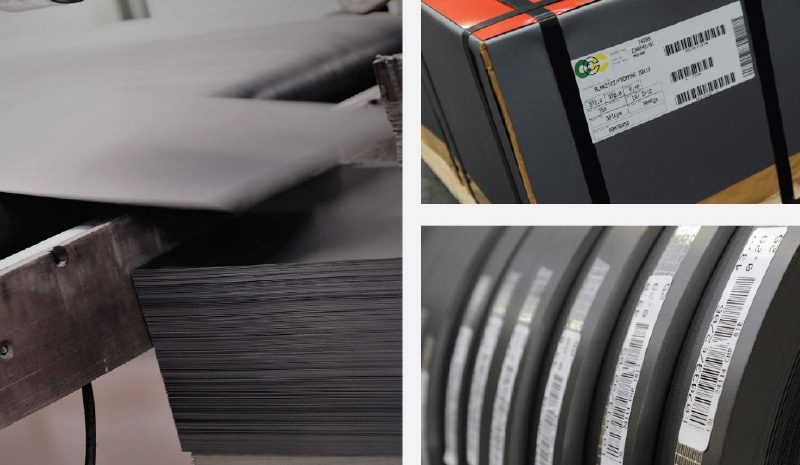

Finishing Services

Our material can be supplied cut to size in coil or sheet form with or without a protective film.

Coils are provided on a 406 or 508mm ID at widths from 25mm to 900mm to tolerances of +/- 0.20mm.

Blanks can be cut to almost any size from a minimum 220mm x 150mm

All material is suitably packed for safe transit and according to the standard of the receiving country.

Testing

The specifications presented by CCC are underwritten by extensive testing carried out on metals and coatings that benchmark performance. These include cooking & abrasion tests as well as the testing of metal substrates to ensure that the material supplied will make the products for which it is intended.

Additionally in-line process monitoring and testing that covers adhesion, colour, flexibility and cure are performed as standard.

Delivery Logistics

Our customers are located all over the globe and we manage the logistics through our freight forwarders.

Supply is generally in 20 tonne lots by dedicated lorry or container.

Distribution into the Far East is handled by Nishitani & Co. Ltd our exclusive agency.